Experience

PRE Edward Biel started its business in 1993. Thanks to our modern and efficient paint line, we provide painting services to an increasing number of external customers. The core scope of our business is the production of electrical switchboards.

Powder coating of aluminum and steel components is one of the stages in the entire production of switchgear. We employ qualified personnel with years of experience in powder coating, which translates into high quality workmanship.

Scope of services

We provide full powder coating services. We perform painting of elements:

| Aluminum | among others – profiles – frames (motorcycles, bicycles) – sheet metal – housings ( single and double shell) – structures – facades – rims – elements for construction (facades) – cabinets |

| Steel (black and galvanized) | Among others – profiles – frames – sheet metal – casings – balustrades, gates, fences, poles, railings – structures (e.g., advertising signs) – rims – elements for the construction industry (facades) – railroad equipment – fire extinguishers – machine components. |

Glass – decorated

Painting in the full RAL color palette of leading manufacturers.

Powder coating line

Powder coating curing oven. Working chamber dimension:

- width: 1,20 m

- height: 2,65 m

- length: 5,0 m

Maximum temperature: 200 degrees C

- SPEAT powder coating booth

- Sames application devices

Compliance with standards

Our powder coating line complies with European standards, in particular: MACHINERY DIRECTIVE 89/392 CE.

We have certificates proving the highest quality of manufactured products:

PN-EN ISO 4628

“Paints and varnishes – Evaluation of deterioration of coatings – Determination of the amount and extent of damage and intensity of uniform changes in appearance – Part 6: Evaluation of the degree of chalking by the tape method”;

PN-EN ISO 2409

“Paints and varnishes – Testing by the notch grid method;”.

EN 50050:2011

Scope of Design Services

Preparation of projects by educated and experienced designers guarantees you a high level of proposed technical solutions that are support for contractors and investors.

This is because we have to offer not only innovative designs tailored to the customer’s requirements in the prefabrication of switchgear cabinets, durable and aesthetically pleasing execution , but also comprehensive designs of facility installations with pre-fabrication and execution of switchgear and facility cabinets.

PRE Biel’s Design Department also employs people authorized to carry out investor supervision and design electrical and power installations for investments throughout the country.

In our newly established design office, we are engaged in comprehensive development:

- conceptual designs;

- construction projects;

- tender projects;

- electrical installation projects;

- MV and LV power networks and facilities;

- telecommunications projects.

We prepare estimates with specifications of works and ready design for newly built facilities or their expansion, in terms of:

- Lv/Mv pole stations;

- Container and indoor MV/Lv substations;

- MV and LV power connections;

- MV and LV main switchgear and LV object switchgear;

- MV and LV overhead and cable lines;

- Street and facility lighting;

- Electrical installations in industrial, multi-family, etc. facilities;

- lightning protection installation;

- teletechnical installations.

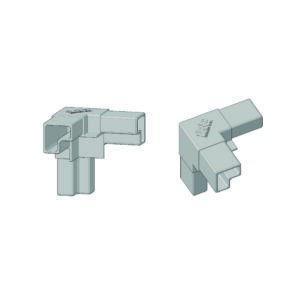

Machining of steel and aluminum sheets

Our company has been engaged in steel and aluminum sheet metal processing in the field since its inception:

- cuts;

- punching;

- bending;

- welding;

- sandblasting;

- powder coating.

We offer full consulting and the possibility of carrying out the project or working on entrusted projects.

We have the ability to process:

- Steel sheets up to 4 mm thick;

- Aluminum sheets up to 5-6 mm thick;

- Steel and aluminum profiles of any shape.

We also have our own transportation. We cordially invite all interested parties to cooperate with us, we accept individual and serial orders.

Laser engraving

We offer laser engraving marking service in metal, plastic and other materials and elements such as:

- wood;

- promotional items;

- metal;

- paper;

- stamps;

- skin;

- glass;

- fabrics;

- trophies;

- plastics;

- nameplates.

We have a tabletop engraving laser with a powerful CO2 laser source. This allows us to engrave a wide variety of materials in a very short time. The working area of the device is 457×305 mm, which allows us to make any format.

We have software that allows us to make any graphic signs. We invite all interested parties to cooperate with us, we accept individual and serial orders.