Application

KSW and KSZ containerized transformer stations are designed to power urban consumers, construction sites, industrial plants from cable or overhead-cable medium-voltage networks.

Implementation

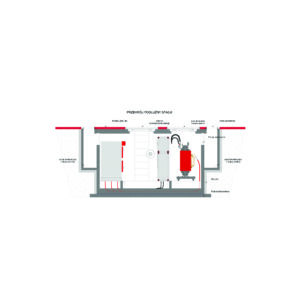

Enclosures of containerized transformer stations are made in the form of elements that are monoliths. Self-compacting concrete SCC class C30/37 is used for production. Stations with external service (KSW) consist of three independent elements:

- cable cellar

- main body

- roof

Externally operated substations (ASCs) and MV cable connectors are made up of 2 components:

- main body

- roof

Cable cellar made of a uniform prefabricated structure that is also the foundation of the station. A partition is made in the cable basement to separate the cable compartment from the part serving as an oil sump. This sump is capable of holding all the oil from transformers installed in the station in case of their failure. The exit of cables from the foundation is carried out through sealed cable penetrations. The entire surface of the cable cellar is coated with means to ensure water and oil tightness.

Main body is a monolithic system of four walls and a floor made of self-compacting concrete SCC class C30/37. In the main body are mounted MV and LV switchgears, metering panels, telemechanical cabinets, transformers and other equipment of the station. Underneath the switchboards, penetrations are made in the floor in order to run cables to the station foundation. At the request of the client, in order to achieve the required fire resistance class (up to REI 120), fireproof panels are fixed on the inside of the walls.

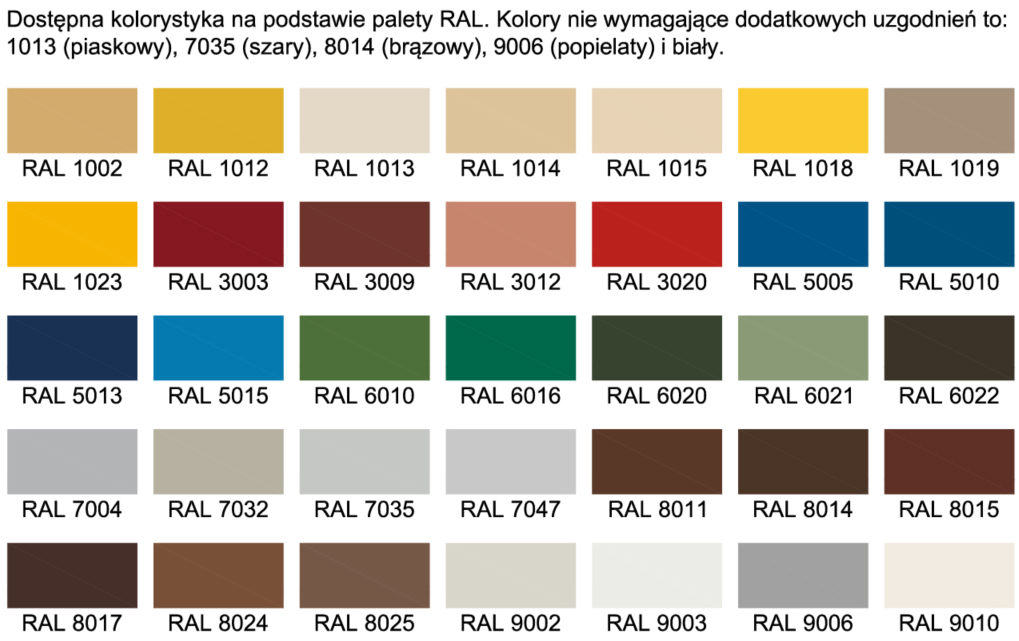

The outer surface of the walls is covered with acrylic plaster. The standard color scheme of the station is given in the table. It is possible to use a different color scheme or a different type of station facade. The inner surface of the housing is covered with acrylic plaster in white as standard.

Separate doors are provided for the transformer compartment and the compartment with switchgear, made of steel sheet (aluminum doors on request) powder-coated in any RAL color. The doors are equipped with ventilation louvers for equipment cooling and room ventilation.

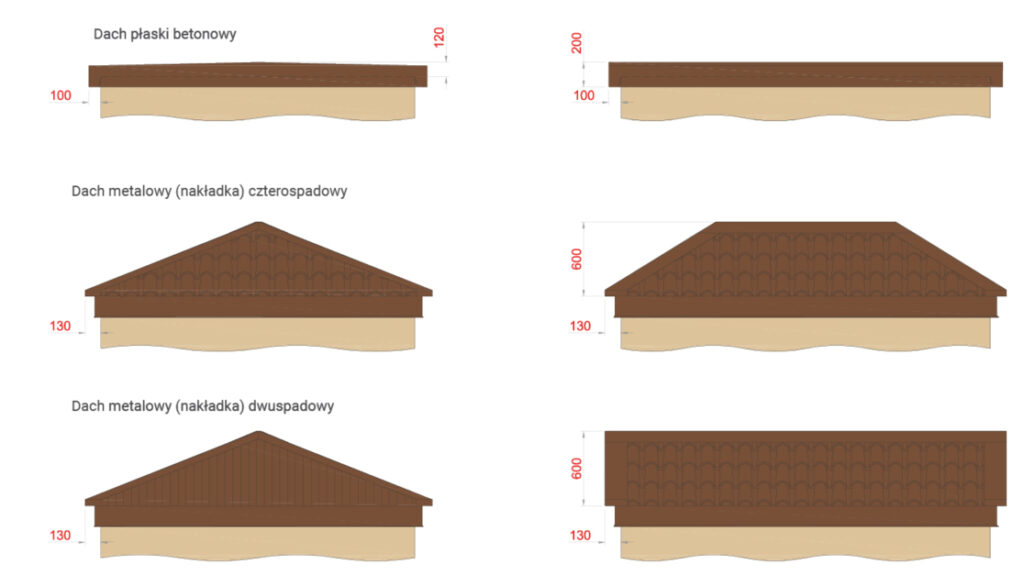

Roof It is seated on the walls of the station on elastomeric pads. It is made in the form of a rectangular reinforced concrete slab with a thickness of: 130mm in the center, 90mm at the edges. Variable thickness is used to achieve a 2.2% slope. The outer surface of the roof is painted with weather-resistant paint in RAL colors. It is also possible to make the roof in variants of two- or four-slope overlays adapted to the architectural requirements. Covering of the overlays can be made of sheet metal or ceramic tiles.

Equipment

Apparatus

Apparatus is selected to meet the individual needs of the customer and the professional power industry. The offered solutions take into account the optimization of performance in terms of technical and economic aspects. In order to satisfy a wide range of customers and meet their individual needs, our stations are approved for use in the professional power industry with the following types of switchgear.

Performances of individual stations also take into account the possibility of using other apparatus. Detailed data on the products used can be found in the catalogs and DTRs of individual devices on the websites of their manufacturers.

MV switchgears

We use switchgear from several manufacturers, which we select according to individual needs. We use switchgear in air insulation and in SF6 insulation. Switchgears are adapted for operation in Smart Grid networks. Switchgears are made of individual fields with any equipment, which, when combined together, form a fully functional switchgear. The configuration and parameters of the switchgear depend on the selected manufacturer, we offer, among others:

our own production – RSS-24w, Schneider – RM6, SM6, ABB – SafePlus, SafeRing, UniSec; Efacec Normafix, Fluofix; Eaton – Xiria; Siemens – 8DJH.

Available fields:

- linear

- breaker

- transformer

- measuring

- clutch

- rail

Transformer

The transformer is selected individually for the project, taking into account the parameters of power supply, quality, and characteristics of the object. The connection between LV /SN switchgear and the transformer is made by cables. It is also possible to make a low-voltage connection using busbars, or rail bridges.

RWT LV switchgear

The switchgear is built on the basis of a modular housing that provides a rigid structure in which LV apparatus is mounted.

The switchgear can be configured according to your needs and can include the following modules:

- MZ power supply module

- MO drain module

- MP measuring and balancing module

- MA aggregate module

- SON lighting module

- MBK capacitor battery module

The RWT switchgear is additionally equipped with protection of own-needs (PW) circuits, which include station lighting, 230 V outlet and additional circuits depending on the project. In the case of KSZ-type stations, RWTz-type LV switchgear is installed in the enclosure.

For a detailed description of RWT and RWTz switchgear, see the chapters dedicated to them.

Other station equipment:

- Door and ventilation joinery

- Lighting and grounding installation

- Fans

- Fire dampers

- Sealing systems for LV and MV cables

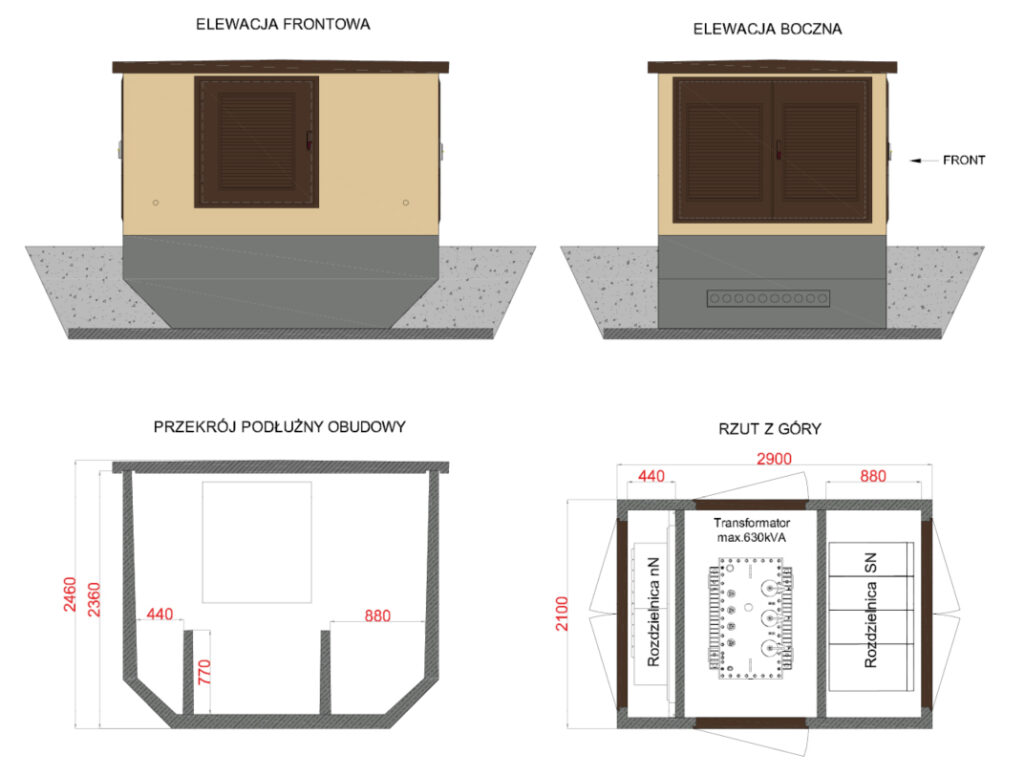

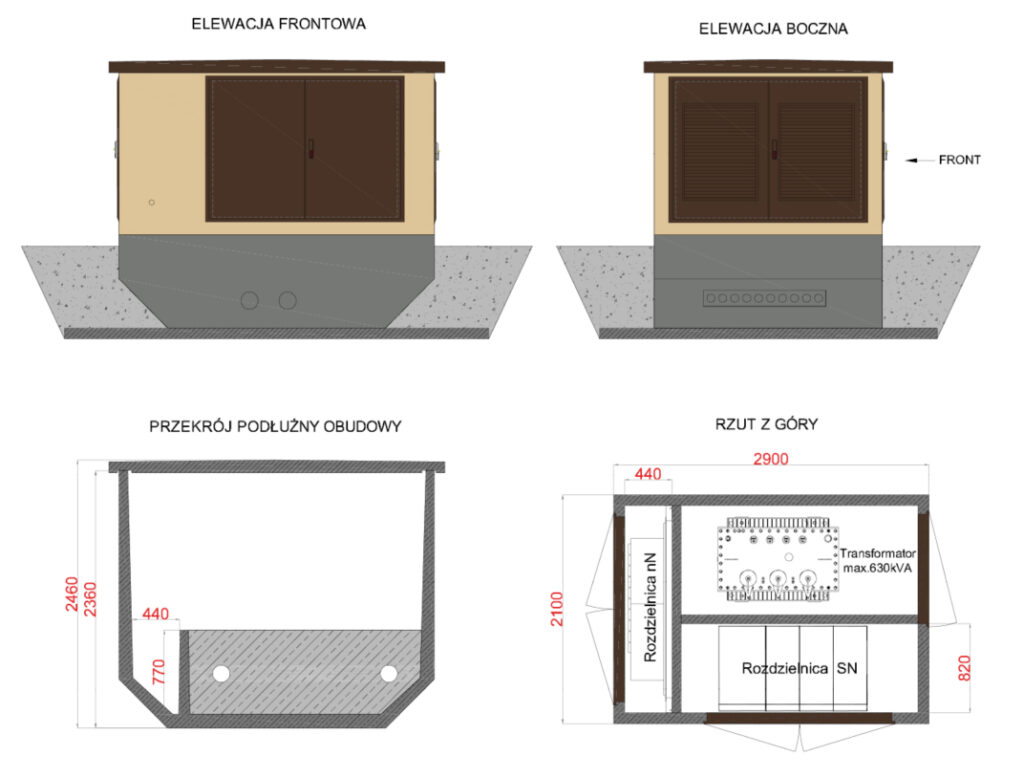

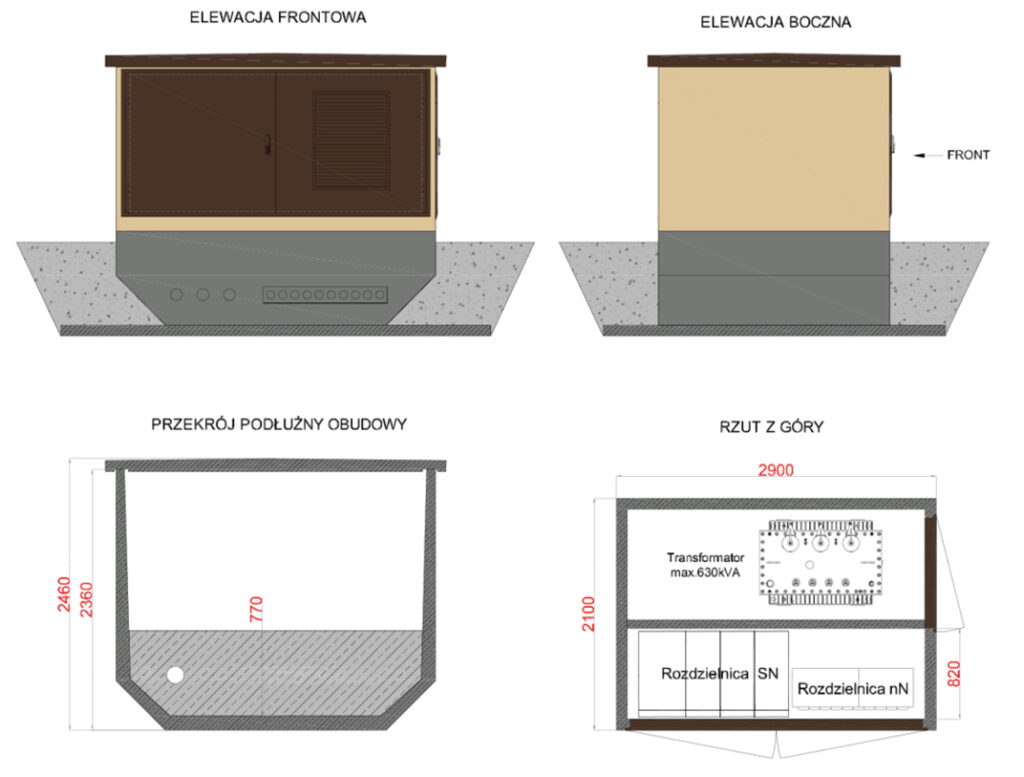

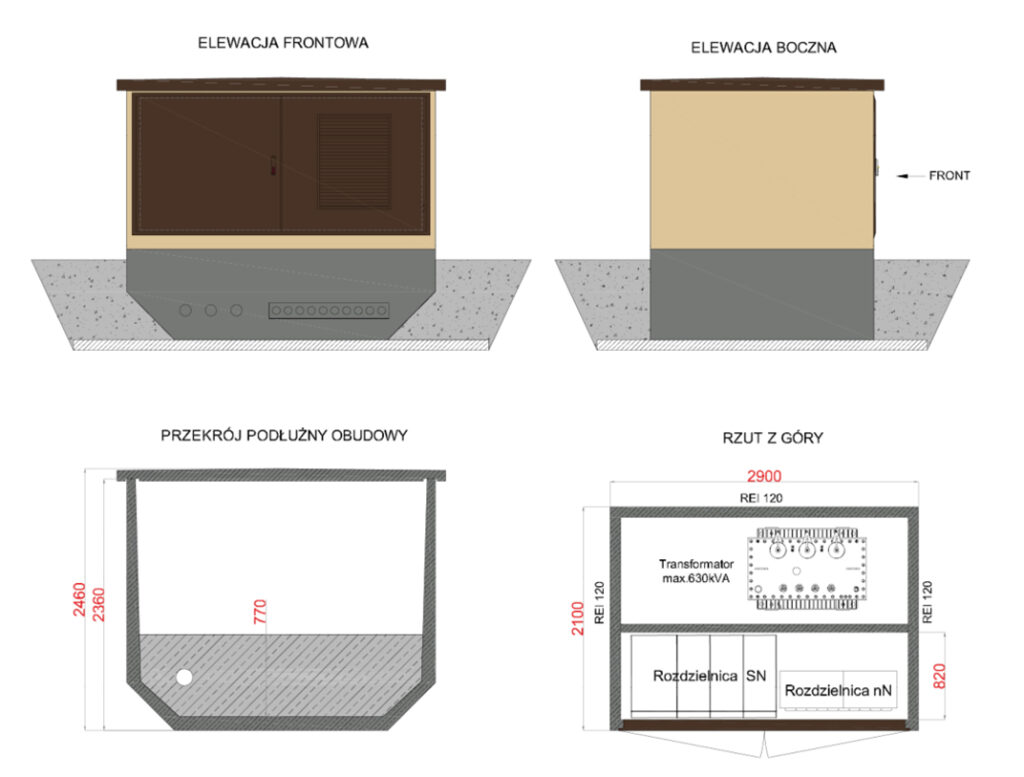

TYPES OF ENCLOSURES – CONTAINER TRANSFORMER STATIONS KSZ

The stations have external dimensions of 2.9 m x 2.1 m (L x W). Their small dimensions make them ideal for densely built-up areas.

The station can be made in four variants:

A – Parallel location of MV and LV switchgear in relation to each other.

B – Perpendicular location of MV and LV switchgear with respect to each other.

C – MV and LV switchgear located in relation to each other with one common door.

C FIRE – MV and LV switchboards located in relation to each other with one common door. Three walls and the roof are elements of fire separation.

OPTION A

| Outer width: | 2,1 m |

| Outer length: | 2,9 m |

| Overall height: | 2,5 m |

| Height after foundation (from p.ground): | 1,65 m |

| Mass of the main body: | 7,5 t |

| Roof weight: | 2,1 t |

| Total weight: | 9,6 t |

OPTION B

| Outer width: | 2,1 m |

| Outer length: | 2,9 m |

| Overall height: | 2,5 m |

| Height after foundation (from p.ground): | 1,65 m |

| Mass of the main body: | 7,5 t |

| Roof weight: | 2,1 t |

| Total weight: | ~9,6 t |

OPTION C

| Outer width: | 2,1 m |

| Outer length: | 2,9 m |

| Overall height: | 2,5 m |

| Height after foundation (from p.ground): | 1,65 m |

| Mass of the main body: | 7,5 t |

| Roof weight: | 2,1 t |

| Total weight: | ~9,6 t |

VARIANT C fire protection

| Outer width: | 2,1 m |

| Outer length: | 2,9 m |

| Overall height: | 2,5 m |

| Height after foundation (from p.ground): | 1,65 m |

| Mass of the main body: | 7,5 t |

| Roof weight: | 2,1 t |

| Total weight: | 9,6 t |

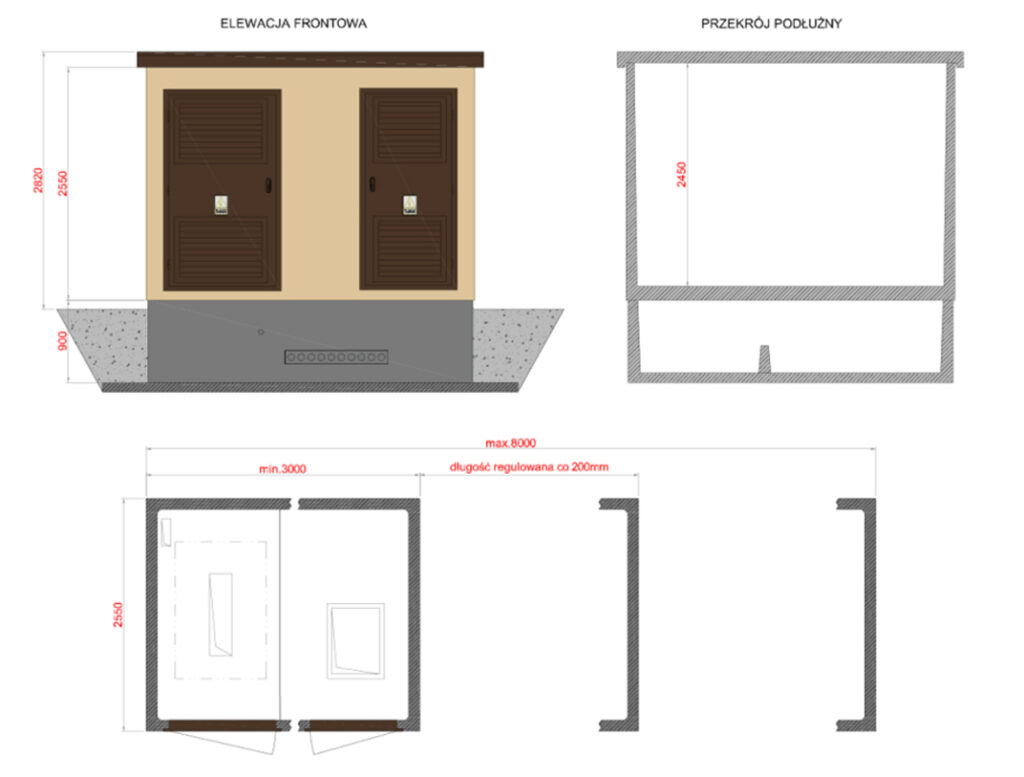

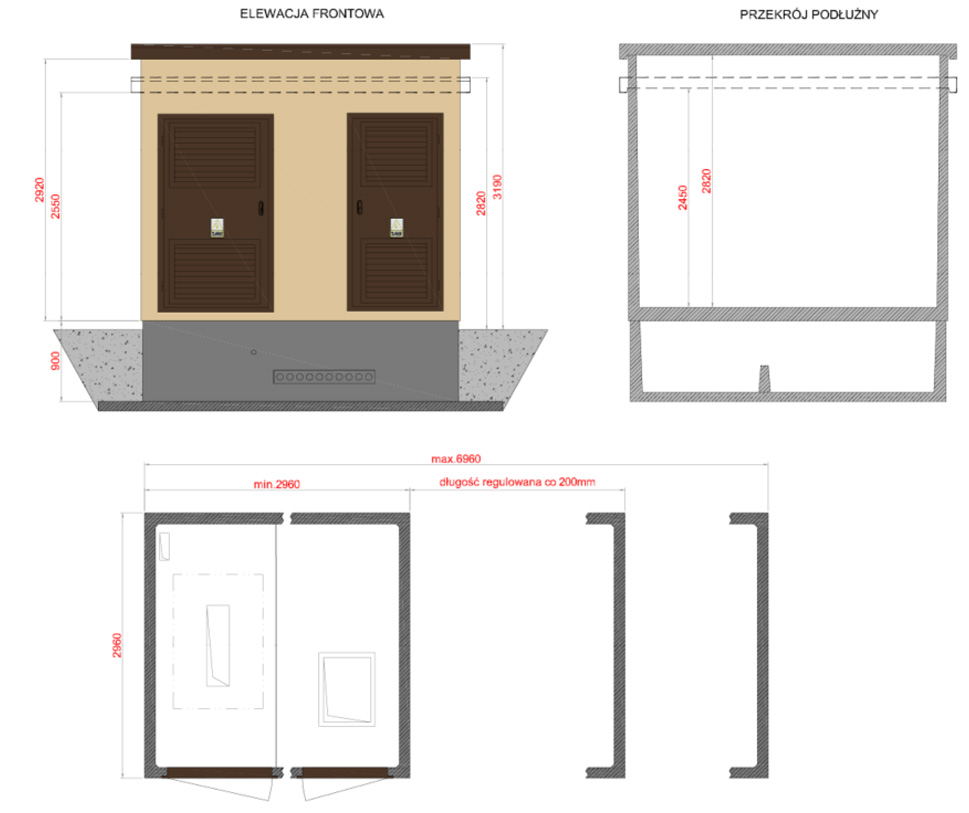

ENCLOSURE TYPES – KSW CONTAINER TRANSFORMER STATIONS

These are freestanding transformer stations with an internal service corridor. They are produced in two basic variants: with a width of 2.55 m and 2.96 m. The variable length of the enclosures allows them to be tailored to individual customer needs. If necessary, the stations can be made with three walls and a roof as fire separation elements.

KSW 255 ENCLOSURE

Thanks to the use of a movable mold, it is possible to make a station in an enclosure with a length of 3m to 8m (in increments of 200mm). The arrangement of devices in the station and the doors and shutters in the enclosure are each time adapted to the project and customer requirements.

| Outer width: | 3 do 8 m |

| Outer length: | 2,55 m |

| Overall height: | 3,62 m |

| Height after foundation (from p.ground): | 2,82 m |

| Mass of the main body: | 16,8 do 38,3 t |

KSW 296 ENCLOSURE

Thanks to the use of a movable mold, it is possible to make stations in an enclosure from 2.96m to 6.96m long (in 200mm increments). It is possible to make stations with heights: 2.55m and 2.92m.The arrangement of equipment in the station and the doors and louvers in the enclosure are each time adapted to the project and customer requirements.

| Outer width: | 2,96 do 6,96 m |

| Outer length: | 2,96 m |

| Overall height: | 3,64 do 4,01 m |

| Height after foundation (from p.ground): | 2,84 do 3,21 m |

| Mass of the main body: | 20,1 do 40,1 t |

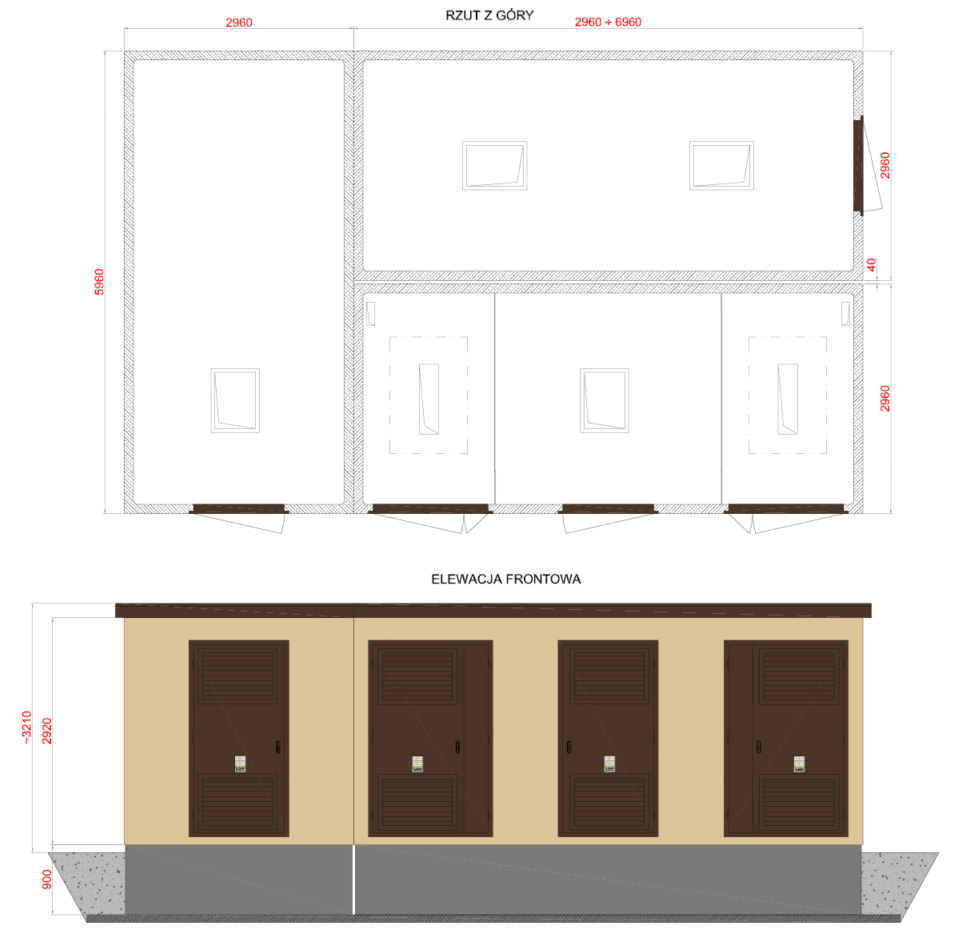

Large-size enclosures – individual designs

In the case of designing equipment, which by its dimensions exceeds the possibilities of placing in a single enclosure, it is possible to configure multi-segment enclosures. Buildings can be connected by shorter or longer walls. We use sheet metal elements to connect the buildings. The selected apparatus should be optimally arranged. In consultation with the customer, we provide proposals for the implementation of the object.

| Outer width: | 2,96 do 5,92 m |

| Outer length: | 8,54 do 13,96 m |

| Height after foundation (from ground p.): | 3,21 do 3,35 m |