Implementation

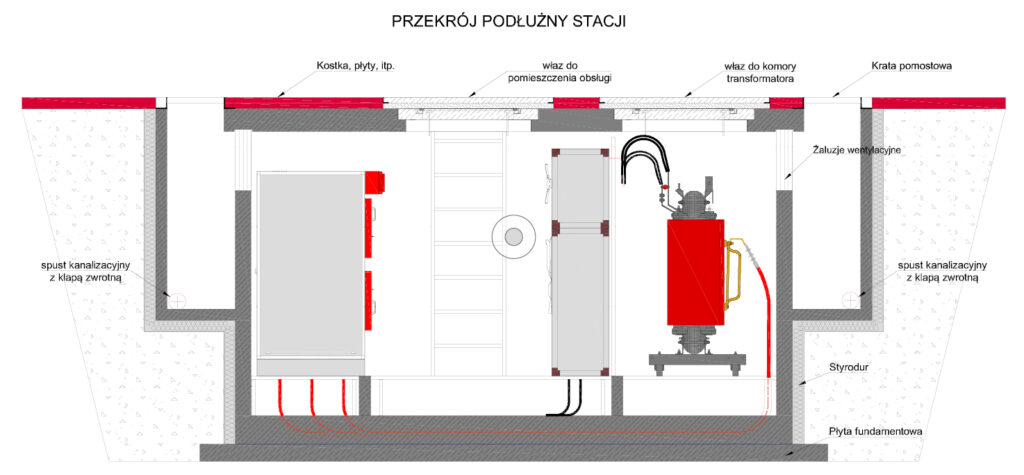

The prefabricated transformer station is a reinforced concrete structure in which the following functional areas can be separated:

- MV switchgear

- LV switchgear

- transformer

- telemechanics and automation

The station has a reinforced concrete floor with process passageways for the entry and exit of cables between the MV switchgear and the transformer. Underneath the transformer is a sealed oil sump, which is used to collect oil from the transformer in case of a leak or failure.

In the side walls of the enclosure are designed sealed cable passages for the introduction and exit of cables to the MV switchgear and LV switchgear. The switchgear room is separated from the transformer by a perforated steel mesh partition.

Heat dissipation from the equipment is provided by gravity ventilation through the use of two sidewalk ventilation grilles at the top of the station housing.

Sidewalk ventilation grilles are made to protect the footwear of passersby and at the same time are resistant to external loads. The housing hatch is made so that technological equipment can be replaced. In the large manhole is made a hatch for service. Manholes are covered with granite elements of the sidewalk. All metal elements exposed to weather conditions are hot-dip galvanized.

The inner surface of the walls is painted with white emulsion paint, while the outer surface is covered with heavy waterproofing compound insulation to eliminate the possibility of water entering the station.

The enclosure was designed taking into account an additional load of 5 kN/m2 as a substitute load of the overrun for a light truck with load or heavy truck without load according to PN-88/B-02014.

Equipment

The equipment of the station is selected each time according to the needs of the customer and the functional requirements that the station must meet.

Product quality

The quality of the product is monitored at every stage of production in compliance with EN ISO 9001:2009. We provide a basic 24-month warranty with the possibility of extension upon request. The station is made of the highest quality materials and tested and certified equipment.

During the warranty and guarantee period, the manufacturer is liable for defects and damage caused by faulty design, use of improper materials or improper workmanship. It is possible to extend the warranty at the request of the customer for the station and apparatus.

Location

The station is designed for urban areas with dense buildings, parking lots, plazas and places where there are difficulties with the installation of a traditional station. When locating the station housing, distances between buildings and off-road equipment should be maintained, as well as distances from the boundaries of the plot and from buildings on neighboring building lots.

Features

• walls– Vibrated reinforced concrete class C30/37, wall thickness 14 cm,

• bottom plate – reinforced vibrated concrete of class C30/37, slab thickness 25 cm,

• floor slab – reinforced vibrated concrete of class C30/37, slab thickness 20 cm,

• ventilation louvers – aluminum covered with paint in color according to RAL palette,

• external ventilation grilles (bridges) – galvanized steel,

• manhole (cover)– hot-dip galvanized steel.